Restoration of a 1918 Harley Davidson Bicycle – Part 5: Nickel Plating

Haven’t read part one yet? Check it out first!

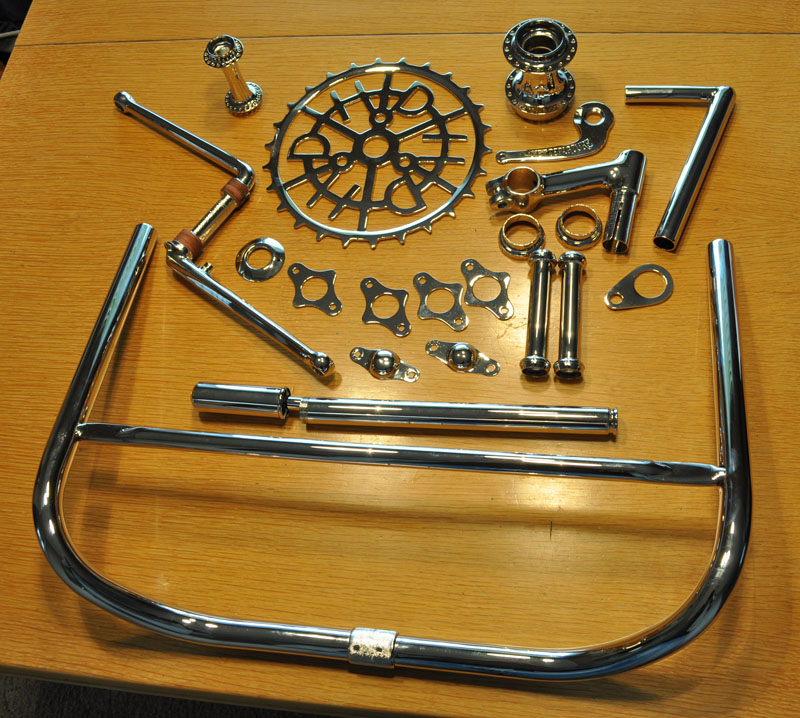

Just back from the plating shop! The shiny parts came out shiny, and they look great! Spokane Metal Finishing did the job for me, and I’m happy with the results.

Nickel plated parts, fresh from the chrome shop

One fear that I always have when handing over a box full of rare and very valuable parts to a chrome shop, is that something will be lost, damaged, or plated poorly. There’s just no getting around it… at some point you have to trust someone else to do part of the job. Fortunately, everything came back looking very nice, and nothing was lost.

You’ll notice in the photo that the threads on the crank are copper colored. This is because the thicker nickel plating would “build” too much into the threads, making it impossible to thread the bearing races onto them. Experienced plating shops will mask these for you, but if you’re worried about it, it doesn’t hurt to ask them to do it, just in case. Even being masked, there is still usually a slight edge that will need to be filed down. I had to do that this time (and every other time I can recall). On rare occasion, the thickness of the sprocket teeth may become too wide to nicely fit the chain! Pretty rare, but it has happened to me once.